Experience the Power of a

Finely Tuned Engine

Give your engine the attention it deserves and maximize the

performance and reliability with our expert tune-up solutions.

What Does Mackeyboys

Tune-up Consist of?

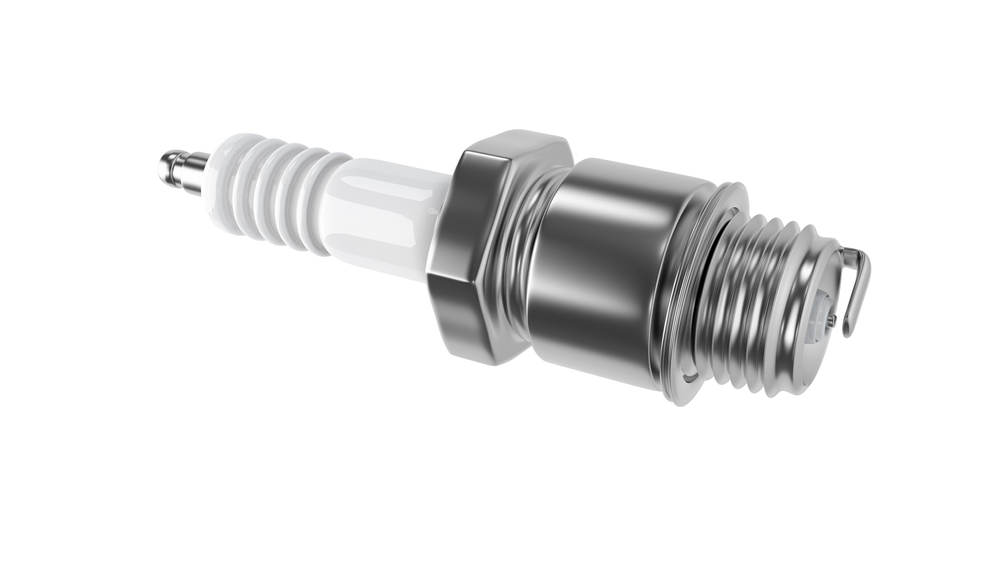

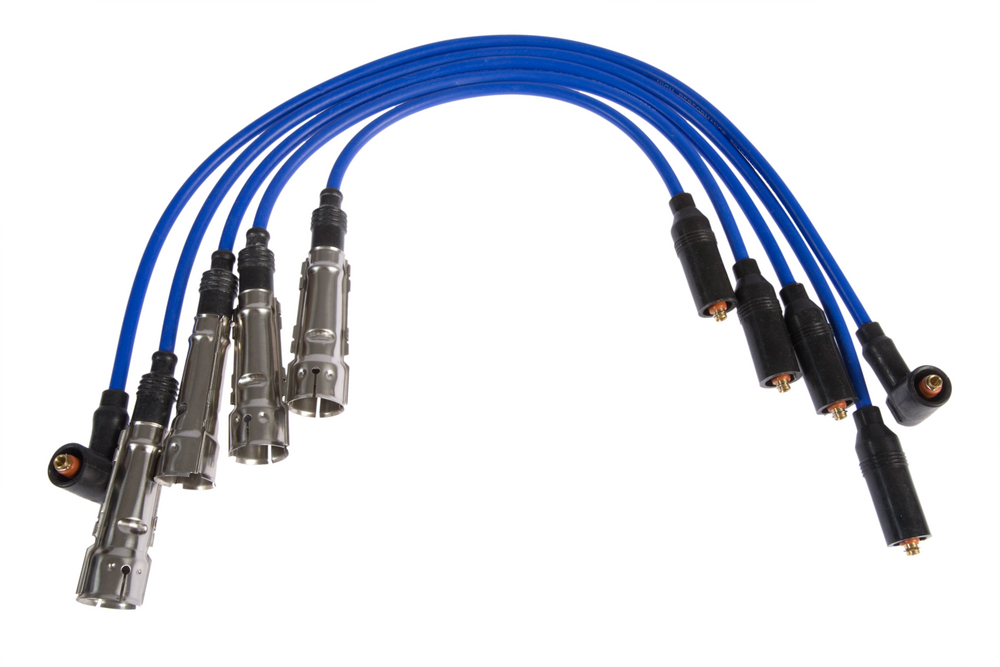

1. Replace Plugs, Wires, and Other Ignition Parts

The ignition system includes spark plugs, plug wires, coils, and other components that ignite the air/fuel mixture in the combustion chamber. Modern systems require changing spark plugs and wires/coil boots at specific mileage intervals, while older systems may have additional parts like a distributor cap and rotor, or breaker points.

Spark Plugs

For distributorless ignition systems (DIS) where one coil is used for multiple plugs, it is crucial to follow the manufacturer's recommendation and use either Double Platinum or Iridium plugs.

Ignition Wires

Ignition Coils

Distributor Cap, Rotor, and Breaker Points (if applicable)

2. Ensure a Clean Engine with Fresh Filters

Your vehicle relies on various filters, including oil, fuel, air, and cabin air filters, to prevent harmful particles from reaching critical engine components. By maintaining clean filters, you enhance engine performance and efficiency. Conversely, dirty filters can strain your engine and impede the delivery of essential air, fuel, or oil at optimal pressure. Ensure your filters are clean to keep your vehicle running smoothly.

Engine Air Filter

Cabin Air Filter

Fuel Filter

PCV Valve

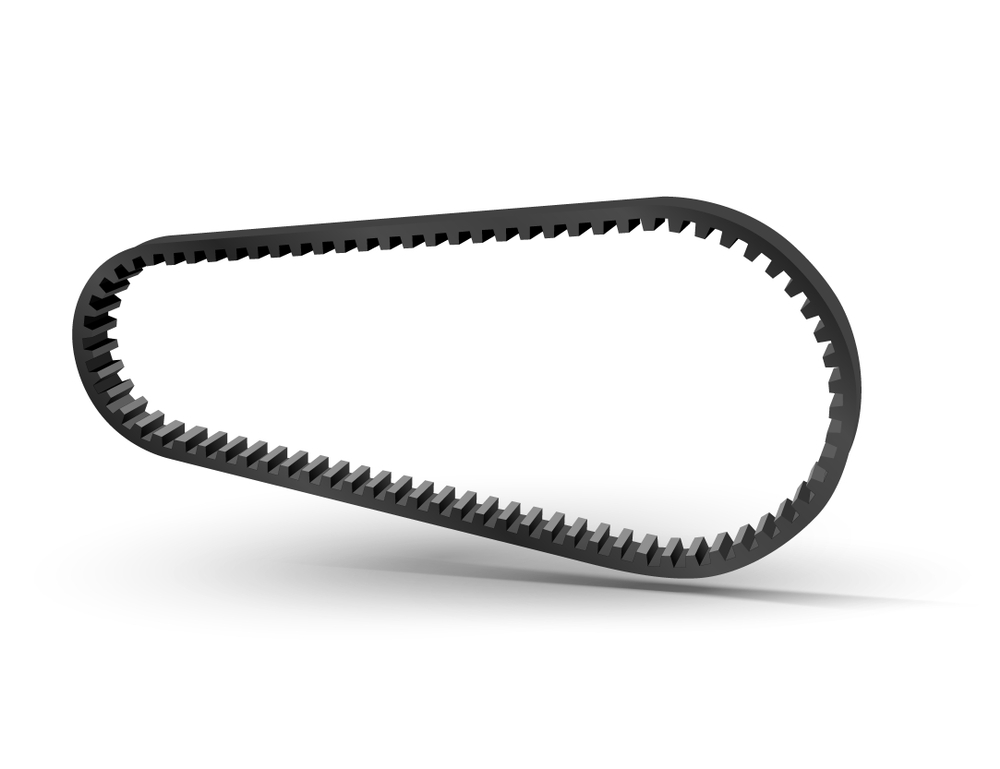

3. Ensure Optimal Performance of Auxiliary Systems with Fresh Belts and Hoses

Belts play a crucial role in transferring power from the crankshaft pulley to various accessory systems, while hoses ensure the proper flow of fluids throughout the engine. However, constant exposure to heat, cold, and regular use causes belts and hoses to deteriorate over time. Eventually, they become worn, brittle, cracked, and may even break, compromising the performance and reliability of your vehicle.

Serpentine Belt

Belt Tensioner

Timing Belt

Hoses